JKMD Multi-rope Friction Hoist

Cagories:

Keywords:

Hotline:

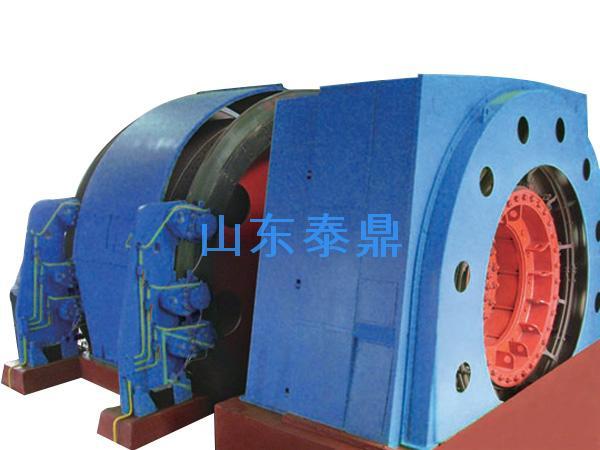

JKMD Multi-rope Friction Hoist

This product is designed and manufactured according to AQ1036-2007, "Safety Inspection Specification for Multi-Rope Friction Hoist for Coal Mine", GB/T10599-1988 "Multi-Rope Friction Hoist", "Coal Mine Safety Regulations", Q/XTD005-2010 "Multi-Rope Friction Hoist" and the current relevant mining machinery product standards. Mainly used in coal mines, metal mines, non-metallic mines ground shaft, for lifting minerals and lifting personnel, materials and equipment.

Working Principle:

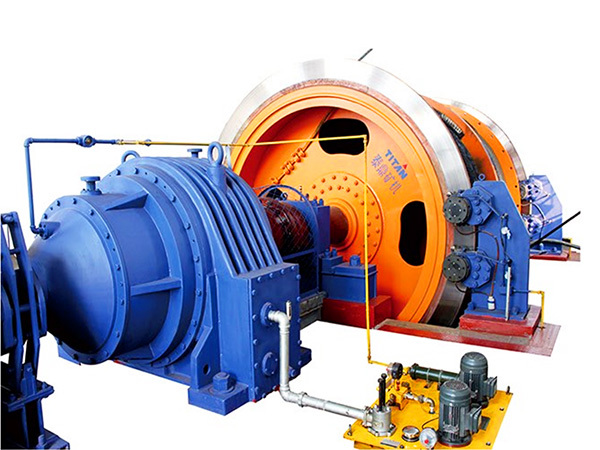

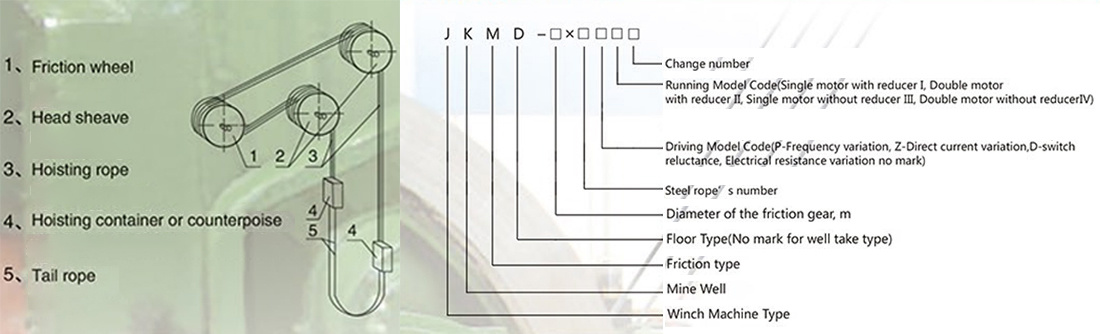

Friction hoist is the use of friction to transmit power, wire rope on the friction wheel of the friction village pad, lifting the container hanging in the ends of the wire rope, hanging at the bottom of the container balance wire rope, lifting the tensioned wire rope to a certain positive pressure pressed tightly on the friction wheel, the wire rope under the action of friction and friction wheel together, so as to achieve the lifting or lowering of the container, the series of hoist through the electrical drive to achieve speed regulation.

Lifting diagram Model Meaning

JKMD technical features

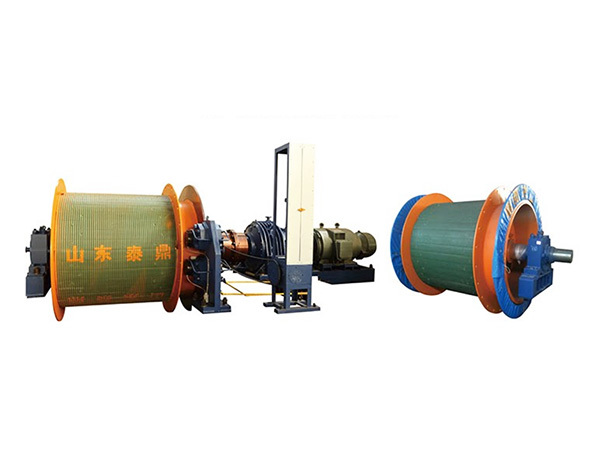

1、The spindle and hub are forged as a whole, and the hub and friction spokes are connected with high strength bolts.

2、Friction liner adopts high performance friction liner, with high friction coefficient and good wear resistance, absorbing the vibration energy of wire rope, preventing wire rope from twisting, not being wet, and strong corrosion resistance.

3、The friction wheel adopts all-welded structure, and the spokes adopt the whole spoke plate type.

4、The rolling bearing uses double-row radial spherical roller bearing, which allows micro-jumping around the center of the bearing to supplement the angular displacement brought about by the bending of the shaft force.

5、The low-speed shaft of planetary gear reducer adopts gear coupling, and the high-speed shaft adopts elastic bar pin coupling.

6、Brake adopts hydraulic cylinder rear disc brake, and each brake is equipped with brake tile wear switch and disc spring fatigue detection switch.

7、Low-speed DC motor is used, the stator is split type, the rotor is suspended type, directly connected with the end flange of the spindle, driving the work of the coil, which can eliminate the reducer, coupling and motor in the bearing seat and lubrication station, smooth transmission, low environmental noise.

8. DC electric control adopts thyristor-powered armature reverse mode, and selects the main wiring mode according to the system and motor capacity size, when the -group rectifier bridge fails, it can switch to full-load half-speed or half-load full-speed and other emergency operation independent dual-system hydraulic station. jkmd technical features

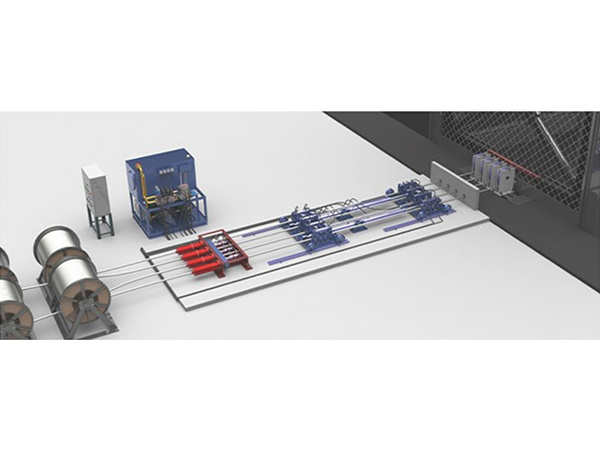

Features of direct link hoist

1、Floor-standing direct-connected multi-rope friction hoist motor rotor and hoist spindle are directly connected by tapered sleeve, low rated motor speed, smooth hoist operation, small maintenance, construction and installation do not occupy the wellhead, can effectively shorten the construction and construction period.

2, the first domestic permanent magnet synchronous motor, synchronous motor electric potential waveform sinusoidal, eliminating the motor in the low frequency torque pulsation problem, high efficiency, small size, no pollution.

| No. | Product Model | Friction diameter | Number of wire ropes | Friction coefficient | Wire rope maximum static tension difference | Maximum tension of steel wire rope | Maximum diameter of steel wire rope | Wire rope spacing | Maximum lifting speed | No wheel diameter | Wire rope elevation angle | |

| With reducer | No reducer | |||||||||||

| m | Root | KN | mm | mm | m/s | m | (。) | |||||

|

1 |

JKMD-1.6x4P I |

1.60 |

4

|

0.25

|

30 |

105 |

16 |

250

|

8.0 |

--

|

1.60 |

≥40至<90

|

|

2 |

JKMD-1.85x4P I |

1.85 |

45 |

155 |

20 |

10.0

|

1.85 |

|||||

|

3 |

JKMD-2x4P I |

2.00 |

55 |

180 |

22 |

2.00 |

||||||

|

4 |

JKMD-2.25x4P I |

2.25 |

65 |

215 |

24 |

15.0

|

2.25 |

|||||

|

5 |

JKMD-2.6x4P I |

2.60 |

140 |

330 |

28 |

300

|

2.60 |

|||||

|

6 |

JKMD-2.8x4P I |

2.80 |

100 |

335 |

30 |

2.80 |

||||||

|

7 |

JKMD-3x4P I |

3.00 |

140 |

450 |

32 |

3.00 |

||||||

|

8 |

JKMD-3.25x4P I |

3.25 |

160 |

520 |

36 |

3.25 |

||||||

|

9 |

JKMD-3.5x4P I |

3.50 |

180 |

570 |

38 |

3.50 |

||||||

|

10 |

JKMD-4x4P I |

4.00 |

270 |

770 |

44 |

350 |

4.00 |

|||||

|

11 |

JKMD-2.8x4Z III |

2.80 |

140 |

330 |

30 |

300

|

|

16.0

|

2.80 |

|||

|

12 |

JKMD-3x4Z III |

3.00 |

180 |

450 |

32 |

--

|

3.00 |

|||||

|

13 |

JKMD-3.25x4Z III |

3.25 |

160 |

520 |

36 |

3.25 |

||||||

|

14 |

JKMD-3.5x4Z III |

3.50 |

180 |

570 |

38 |

3.50 |

||||||

|

15 |

JKMD-4x4Z III |

4.00 |

270 |

770 |

44 |

350 |

4.00 |

|||||

|

16 |

JKMD-4.5x4Z III |

4.50 |

340 |

980 |

50 |

4.50 |

||||||

JKM series multi-rope friction hoist technical performance parameters (well tower type hoist)

| No. | Product Model | Friction wheel diameter | Number of wire ropes | Friction coefficient | Wire rope maximum static tension difference | Maximum static tension of steel wire rope | Maximum tension of steel wire rope | Wire rope spacing | Maximum lifting speed | Guide wheel diameter | |||

| With guide wheel | No guide wheel | With guide wheel | No guide wheel | With reducer | No reducer | ||||||||

|

m |

Root |

KN |

KN |

mm |

mm |

m/s |

m |

||||||

|

1 |

JKM-1.6x4P I |

1.60 |

4 |

0.25 |

50 |

— |

150 |

—- |

160 |

20 |

200 |

8.0 |

— |

|

2 |

JKM-1.85x4P I |

1.85 |

4 |

50/60 |

150 |

180 |

160 |

190 |

22 |

10.0 |

16.0 |

||

|

3 |

JKM-2.25x4P I |

2.25 |

4 |

80 |

210 |

— |

230 |

|

24 |

10.0 |

|||

|

4 |

JKM-2.6x4P I |

2.60 |

4 |

140 |

330 |

340 |

28 |

250 |

15.0 |

||||

|

5 |

JKM-2.8x4P I |

2.80 |

140 |

330 |

340 |

30 |

|||||||

|

6 |

JKM-2.8x4P I |

6 |

180 |

490 |

510 |

||||||||

|

7 |

JKM-3.0x4P I |

3.0 |

4 |

450 |

450 |

32 |

300 |

||||||

|

8 |

JKM-3.0x4P I |

6 |

220 |

650 |

670 |

||||||||

|

9 |

JKM-3.25x4P I |

3.25 |

4 |

180 |

520 |

520 |

36 |

||||||

|

10 |

JKM-3.5x4P I |

3.50 |

4 |

220 |

570 |

590 |

38 |

||||||

|

11 |

JKM-2.8x4Z III |

2.80 |

4 |

0.25 |

100 |

335 |

— |

30 |

— |

250 |

— |

16.0 |

2.80 |

|

12 |

JKM-2.8x4Z III |

6 |

160 |

520 |

|||||||||

|

13 |

JKM-3x4Z III |

3.00 |

4 |

140 |

450 |

32 |

300 |

3.00 |

|||||

|

14 |

JKM-3x6Z III |

6 |

220 |

670 |

|||||||||

|

15 |

JKM-3.25x4Z III |

3.25 |

4 |

160 |

520 |

36 |

3.25 |

||||||

|

16 |

JKM-3.5x4Z III |

3.50 |

4 |

180 |

570 |

38 |

3.5 |

||||||

|

17 |

JKM-3.5x6Z III |

6 |

270 |

860 |

|||||||||

|

18 |

JKM-4x4Z III |

4.00 |

4 |

270 |

770 |

44 |

4.00 |

||||||

|

19 |

JKM-4x6Z III |

6 |

340 |

1200 |

|||||||||

|

20 |

JKM-4.5x4Z III |

4.50 |

4 |

340 |

980 |

50 |

|||||||

|

21 |

JKM-4.5x6Z III |

6 |

440 |

1450 |

4.5 |

||||||||

Product Message

Related Products

Follow Taiding

TaiDingXin Machinery

Contact Us

Address: No.759, Guomao Road, Hi-tech Development Zone, Xintai City, Shandong Province

Tel: +86-538-7058222

Fax: +86-538-7058222

E-Mail: taiding@vip.sina.com

© 2022 Shandong TaiDingXin Machinery Technology Co.Ltd