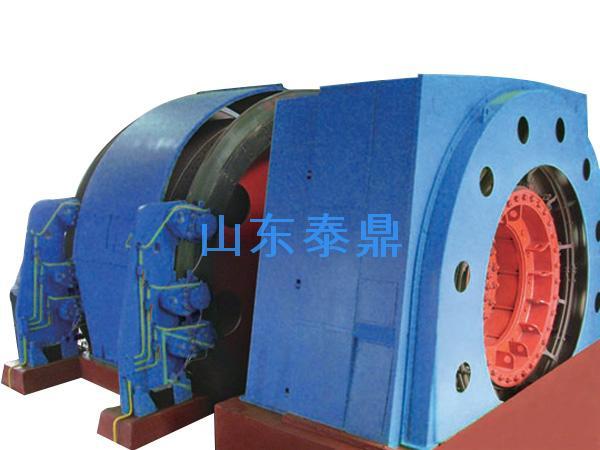

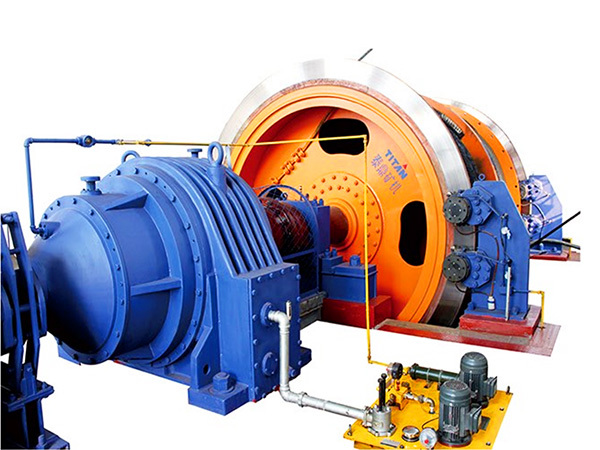

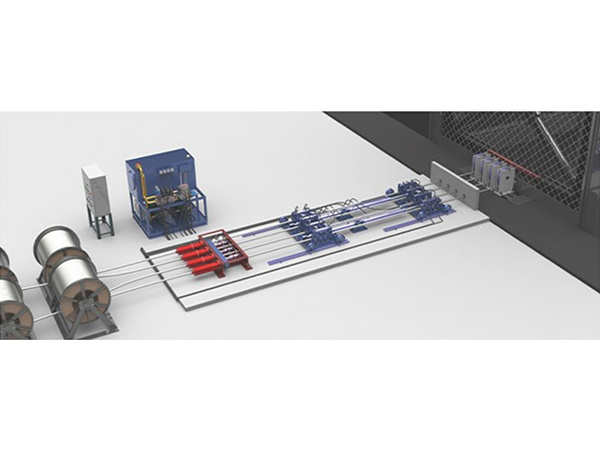

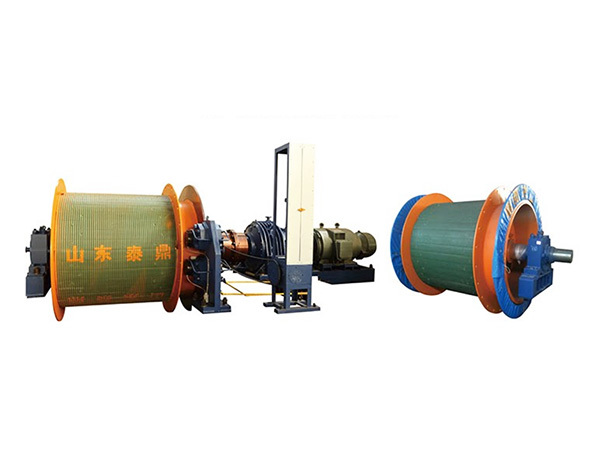

JZ Series Shaft Winch

Cagories:

Keywords:

Hotline:

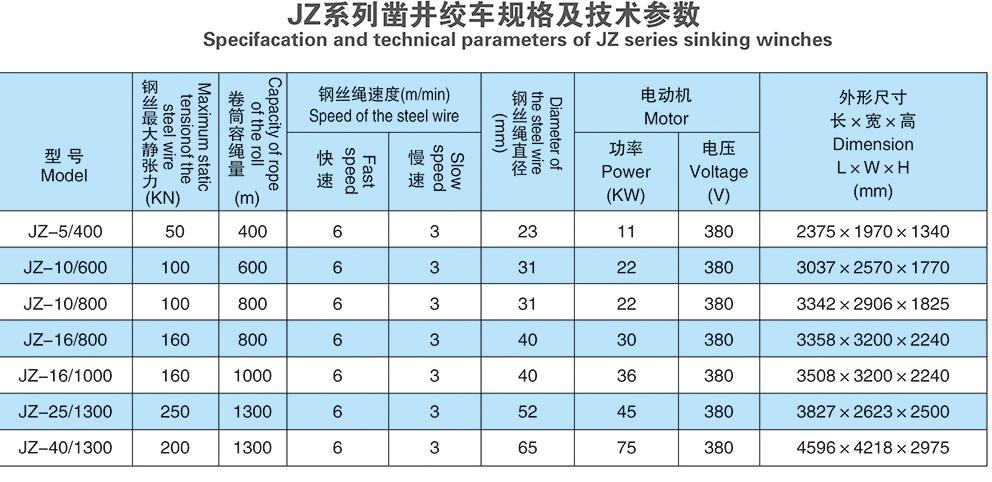

JZ Series Shaft Winch

JZ series shaft winch has the advantages of strong lifting capacity, large rope capacity and smooth operation. It is mainly used in the shaft boring project of metal and non-metal mines to suspend the crane plate, water pump, wind pipe, grouting pipe and other boring equipment and tension the stable rope, and can also be used for lifting heavy objects in other shafts and on the ground.

Product Message

Related Products

Follow Taiding

TaiDingXin Machinery

Contact Us

Address: No.759, Guomao Road, Hi-tech Development Zone, Xintai City, Shandong Province

Tel: +86-538-7058222

Fax: +86-538-7058222

E-Mail: taiding@vip.sina.com

© 2022 Shandong TaiDingXin Machinery Technology Co.Ltd