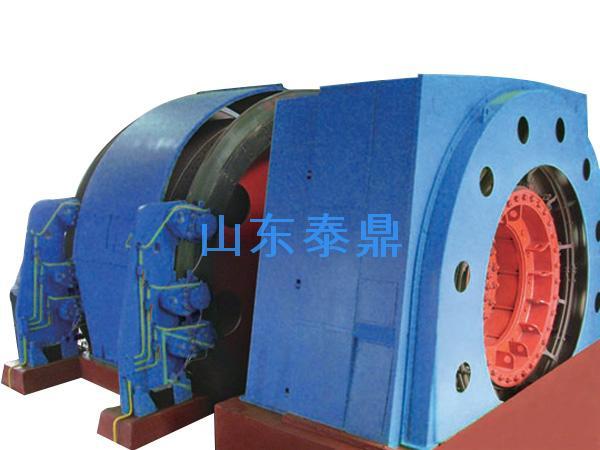

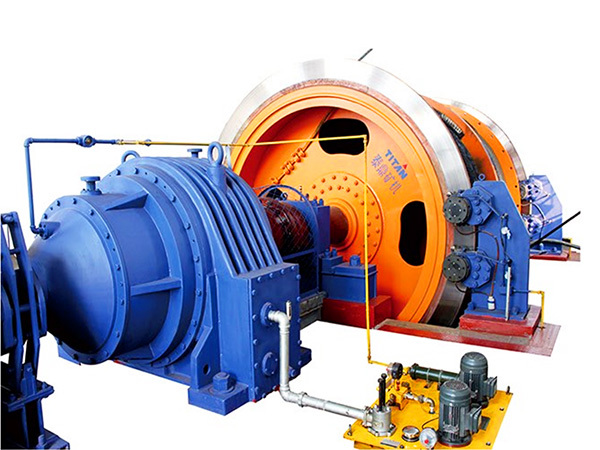

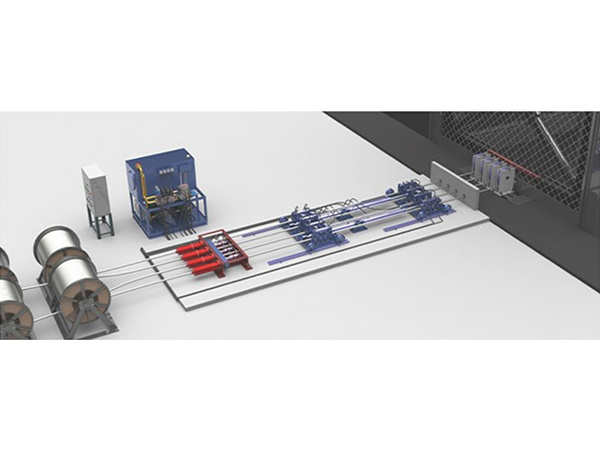

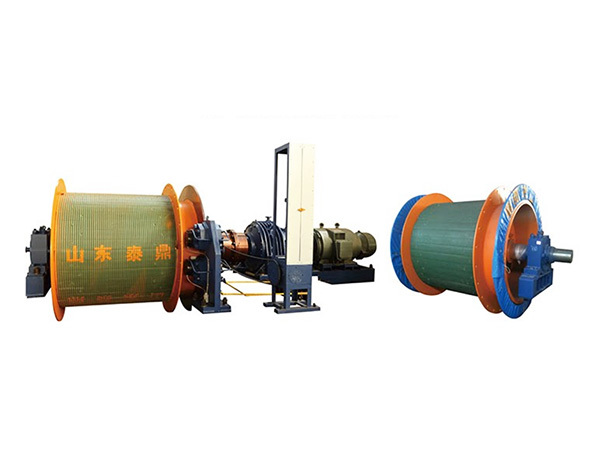

Multi-rope Friction Hoist

Cagories:

Keywords:

Hotline:

Multi-rope Friction Hoist

JKMD Technical Features:

1. Main shaft and hub are entirely forged, and hub and friction spoke are connected with high-strength bolt.

2. It uses high-strength friction pad, with high frictional factor, good wear resistance and strong anti-corrosion, which absorbs vibrational energy of the wire rope, prevents twist of the wire rope, and can’t be soaked.

3. The friction gear uses all- welded structure. The spoke uses entirely radial plate type.

4. The rolling bearing uses double-row self-aligning spherical roller bearing, which allows micro-jumping around the center of the bearing to replenish the angular displacement caused by bending of the shaft.

5. The low-speed shaft of the planetary reducer uses gear coupling, and the high-speed shaft flexible pin coupling.

6. The brake uses rear-hydraulic-cylinder disc brake. Each brake is equipped with brake-shoe wear switch and disk spring fatigue testing switch.

7. It uses low-speed DC motor, with split stator and suspended rotor, directly connected with flange at the end of main shaft to drive the winding drum, thus saving reducer, coupling, and bearing seat and lubrication station of the motor, with stable transmission and low noise.

8. DC electronic control uses thyristor armature reverse control. Select main mode of connection according to the system and motor capacity. When one set of rectifier bridges go wrong, switch into full-load half-speed or half-load full-speed, etc. to run dual-system hydraulic station independently.

Features:

1. The electric rotor and main shaft of floor-type direct-connected multi-rope friction hoist are connected directly with taper sleeve. The rated speed of the motor is low. The hoist runs stably, with little maintenance. In construction and installation, it needn’t occupy the well head, thus shortening construction period effectively.

2. It is the first in China to use permanent magnet synchronous motor, realizing sine wave of internal electromotive force of the synchronous motor, and eliminating the pulsating torque problem of the motor in low frequency, with high efficiency, small volume and no pollution.

Product Message

Related Products

Follow Taiding

TaiDingXin Machinery

Contact Us

Address: No.759, Guomao Road, Hi-tech Development Zone, Xintai City, Shandong Province

Tel: +86-538-7058222

Fax: +86-538-7058222

E-Mail: taiding@vip.sina.com

© 2022 Shandong TaiDingXin Machinery Technology Co.Ltd